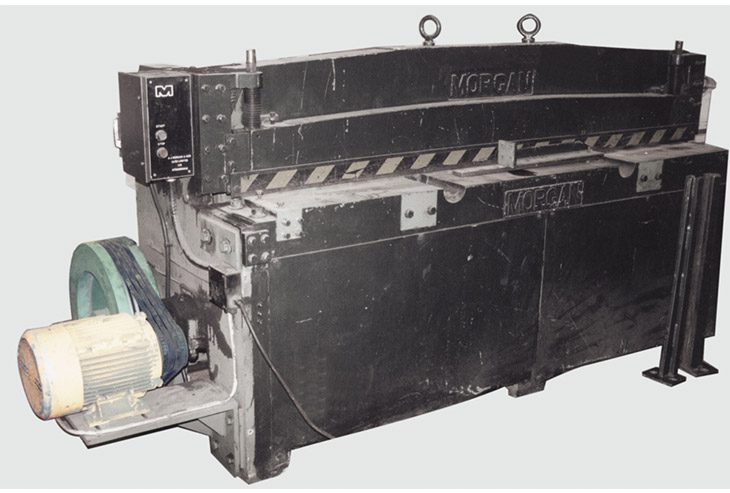

Morgan Rushworth BHGS Hydraulic Swing Beam Guillotine

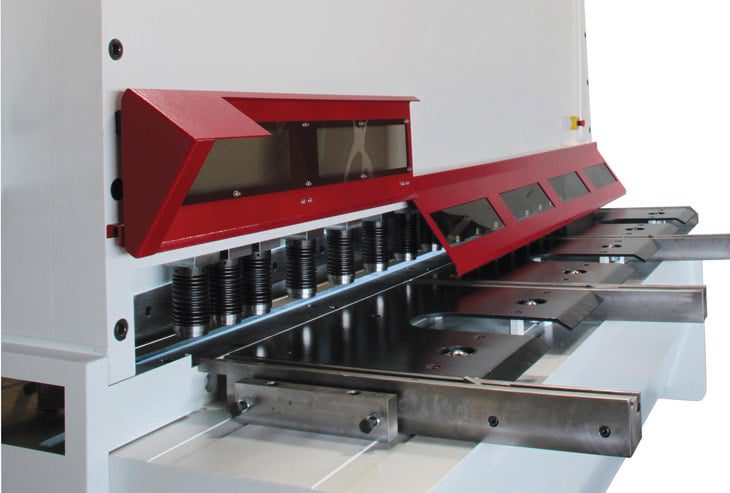

The powerful BHGS range of hydraulic swing beam sheet metal guillotines are equipped with a high visibility front guard design consisting of a fixed guard with windows. All machines are fitted with stainless steel quality cutting blades as standard, giving flexibility to cut a range of materials without detriment to blade life.

The user friendly Cybtouch 6 NC controller ensures accurate cutting with precision back gauge setting and the facility to store complete cutting lists including length and quantity. For longer lengths an automatic swing away backgauge is standard.

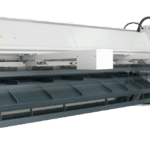

U-Type Pneumatic Sheet Support

U-Type Pneumatic Sheet Support

U-Type Pneumatic Sheet Support

U-Type Pneumatic Sheet Support

| CUTTING LENGTH | CUTTING CAPACITY (45 kg/mm2) | CUTTING CAPACITY (70 kg/mm2) | CUTTING ANGLE | STROKES PER MINUTE | No. OF HOLD DOWNS | MAIN MOTOR | BACKGAUGE MOTOR | BACKGAUGE TRAVEL | OIL CAPACITY | TABLE LENGTH | TABLE HEIGHT | TRANSPORT WIDTH | MACHINE WIDTH | LENGTH | WIDTH | HEIGHT | WEIGHT | ||

| MODEL | STOCK CODE | mm | kw | kw | mm | lt | _A mm | _G mm | _C mm | _C+E mm | _L mm | _C+D+E mm | _H mm | kg | |||||

| BHGS 3100/6 NC | M1062 | 3060 | 6 | 4 | 1.5 | 18 | 17 | 11 | 0.37 | 1000 | 170 | 3340 | 800 | 1600 | 2600 | 3770 | 3100 | 1825 | 7000 |

| BHGS 3100/10 NC | M1063 | 3060 | 10 | 6 | 2 | 12 | 17 | 22 | 0.37 | 1000 | 170 | 3420 | 800 | 1775 | 2775 | 3850 | 3275 | 1850 | 9200 |

| BHGS 3100/13 NC | M1064 | 3060 | 13 | 8 | 2.4 | 12 | 17 | 30 | 0.37 | 1000 | 220 | 3450 | 900 | 1985 | 2985 | 3880 | 3485 | 2060 | 11500 |

| BHGS 3100/16 NC | M1065 | 3060 | 16 | 10 | 2.7 | 7 | 17 | 30 | 0.55 | 1000 | 220 | 3410 | 900 | 2150 | 3150 | 3840 | 3550 | 2230 | 15500 |

| BHGS 3100/20 NC | M1066 | 3060 | 20 | 13 | 3 | 7 | 18 | 37 | 0.55 | 1000 | 280 | 3470 | 900 | 2140 | 3140 | 3900 | 3540 | 2440 | 19600 |

| BHGS 4100/10 NC | M1067 | 4060 | 10 | 6 | 2 | 10 | 23 | 22 | 0.37 | 1000 | 170 | 4370 | 800 | 1975 | 2975 | 4800 | 3375 | 1910 | 13000 |

| BHGS 4100/13 NC | M1068 | 4060 | 13 | 8 | 2.2 | 8 | 23 | 30 | 0.37 | 1000 | 220 | 4400 | 900 | 1975 | 2975 | 4830 | 3375 | 2160 | 16100 |

Features

- CybTouch 6 NC Controller

- Fast and powerful back gauge with 750mm travel

- Automatic swing away backgauge feature

- Stainless steel cutting blades with multiple cutting edges

- Cutting line illumination with shadow wire

- Cutting length stroke adjustment for narrower sheets reducing cutting time

- Digital stroke counter

- Easy blade gap adjustment system from single point

- Powerful hydraulic material hold downs prevent sheet sliding during cutting

- Front guards with windows for excellent visibility of cutting area

- Support table with roller bearings

- 1000mm front squaring arm with tee slot and flip stop

- Front support arms with 1000mm length

- Foot pedal available for single or continuous cutting

- One-piece honed and chrome plated double acting powerful cylinders

- Rear photo-cell guards

Options

- 1000mm backgauge travel in lieu of standard 750mm

- Powered blade gap adjustment

- Pneumatic rear sheet support system

- Tee Slot, flip stop & rule on front support arms

- Angle gauge

- 1 metre lift up finger guard with interlock switch

- Front CE light guards in lieu of standard fixed front guards

- Laser cutting line

- Longer squaring arms and support arms