Deburring, Bevelling & Polishing

A key aspect to any fabrication is the final finish of the material. Our range of deburring, bevelling and polishing machines are integral to this, by removing burrs from cut material, it offers a more professional finish, and makes the material safer to handle for operators too. Bevelling gives a cleaner finish for final fabrication and welding. Our tube polishing machine will dramatically improve the quality of the finish of tubular steel, perfect for projects such as handrails and balustrades.

The Morgan Rushworth slat cleaner is also perfect for maximising the life of your profiling machine's slats. By quickly and efficiently removing the leftover slag from plasma or laser cutting, you can get a clean, level surface on your slats ready for more cutting, without having to replace the slats as regularly.

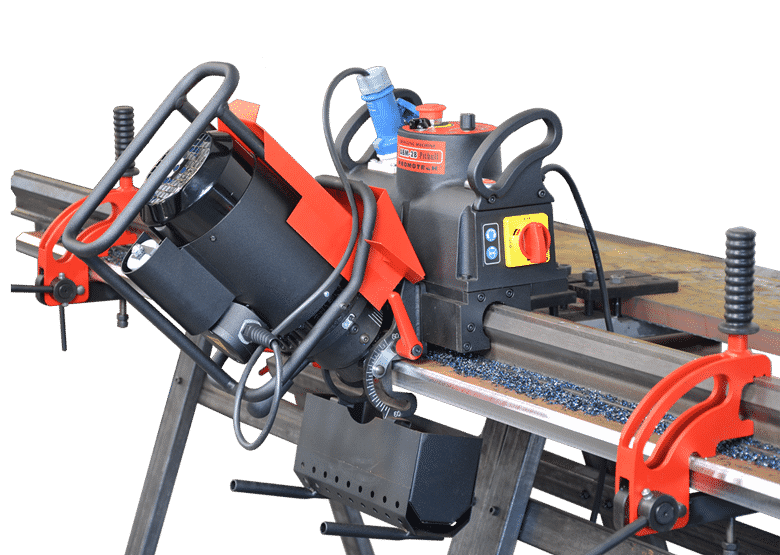

![Curvassi PPM 114 - Tube Polishing Machine [Web - Portrait]](https://selmach.com/wp-content/uploads/2022/08/Curvassi-PPM-114-Tube-Polishing-Machine-Web-Portrait.png)

![Curvassi PPM 114 - Tube Polishing Machine [Web - Portrait]](https://selmach.com/wp-content/uploads/2019/06/Curvassi-PPM-114-Tube-Polishing-Machine-Web-Portrait-200x300.png)