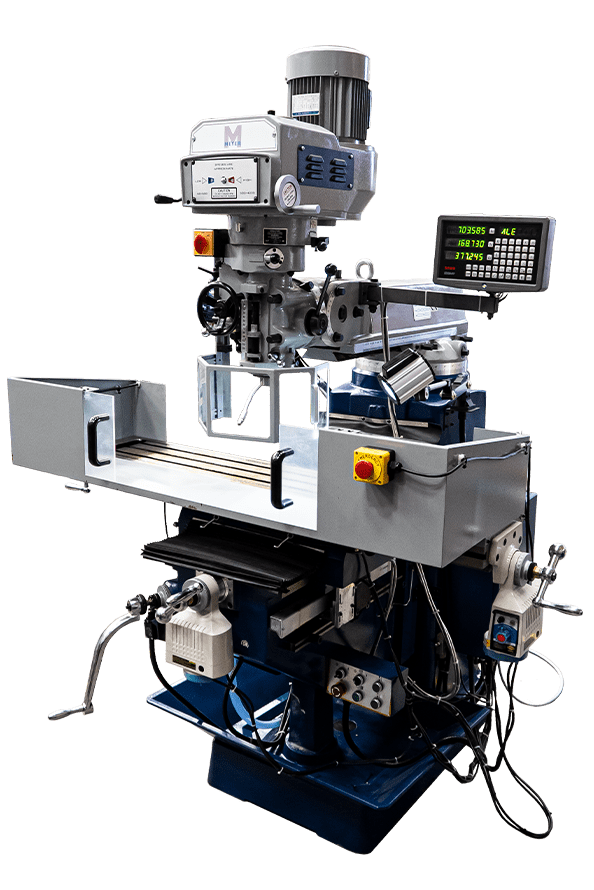

Meyer Turret Milling Machine 415V

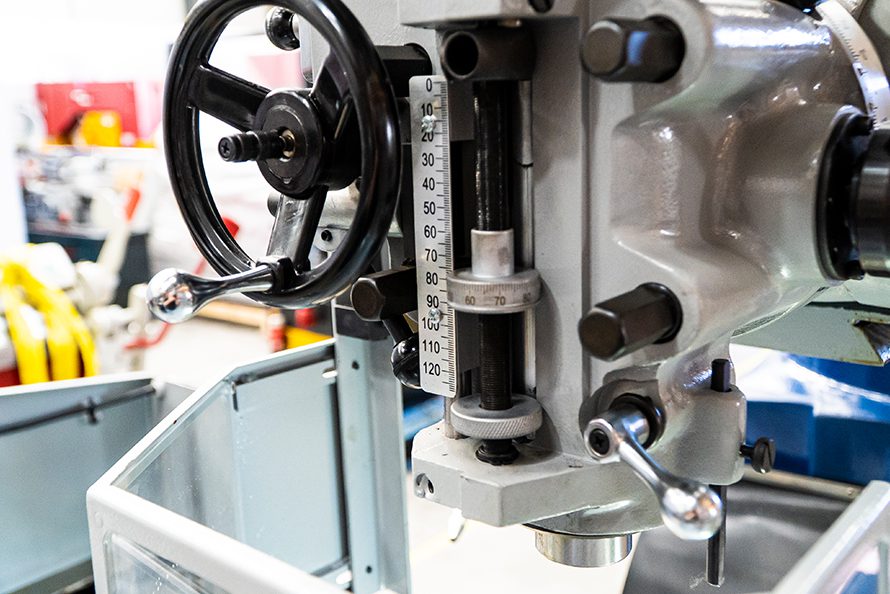

The Meyer Turret Milling Machine 415V are high precision, very accurate and extremely versatile turret milling machines. The turret head can be inclined upwards and downwards, rotated in both vertical and horizontal planes, clockwise and anticlockwise. Each angle can be finely set due to the degree scales for all three variations. X, Y and Z axis are easily and accurately controlled by both the hand wheels, with micrometer scales which can be zeroed, and the intuitive DRO system.

The 220RX model takes R8 tooling whilst the 375S and 560S models driven by powerful motors take ISO40 tooling. Belt driven variable power feed with fast override button is fitted as standard to the X axis on the 220RX models and to X, Y and Z axis on the 375S and 560S machines.

| MODEL | 220RX | 375S | 560S | |

| STOCK CODE | 24200 | 24201 | 24219 | |

| Spindle Taper | R8 | ISO40 | ISO40 | |

| Spindle Travel | 127 | 127 | 127 | |

| Number of Spindle Speeds | mm | Variable (Belt Driven) | Variable (Belt Driven) | Variable (Belt Driven) |

| Spindle Speed | rpm | 60 – 4200 | 60 – 3600 | 60 – 3600 |

| Quill Power Feed | mm/rev | 0.04/0.08/0.15 | 0.04/0.08/0.15 | 0.04/0.08/0.15 |

| Motor | KW | 2.2 | 3.75 | 5.63 |

| Longitudinal Travel – Long | mm | 950 | 950 | 1000 |

| Saddle Travel – Cross | mm | 380 | 400 | 360 |

| Knee Travel – Vertical | mm | 400 | 400 | 400 |

| Max Distance Spindle To Table | mm | 400 | 400 | 450 |

| Table Size | mm | 254 x 1370 | 254 x 1370 | 330 x 1500 |

| Head Movement Left/Right | 90°/90° | 90°/90° | 90°/90° | |

| Head Movement Up/Down | 45°/45° | 45°/45° | 45°/45° | |

| Length | mm | 1670 | 1670 | 2180 |

| Width | mm | 1700 | 1700 | 2050 |

| Height | mm | 2235 | 2235 | 2300 |

| Weight | Kg | 1280 | 1320 | 2300 |

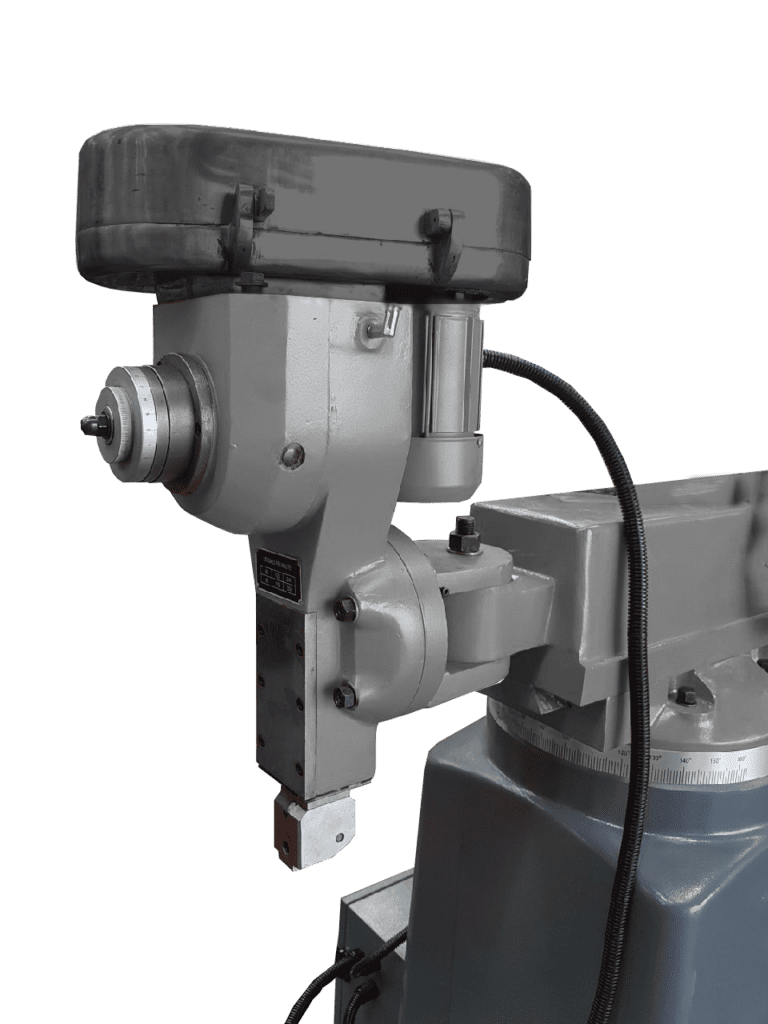

Slotting Head Attachment

| MODEL | SH-100 | SH-125 | |

| Max. Slotting Travel | mm | 100 | 125 |

| Min. number of strokes | RPM | 60 | 60 |

| Max. number of strokes | RPM | 350 | 350 |

| Main Spindle Speed Change | Stepped | 6 steps | 6 steps |

| Tool holder rotation angle | ° | 360 | 360 |

| Motor Power | W | 250 | 370 |

| Weight | Kg | 75 | 87 |

| Machine Dimension | mm | 450 x 300 x 700 | 450 x 300 800 |

Installation information

| MODEL | SH-100 | SH-125 |

| Fitted with T-Plug Indexation Circle | 150 mm | 150 mm |

| Tool holder rotation angle | 360° | 360° |

| Installation Mode | Vertical | Vertical |

| Fitted with T bolts | M12 x 80 | M12 x 80 |

Features

- High accuracy.

- Heavy duty.

- Hardened slideways.

- Centralised lubrication.

- DRO for X, Y and Z axis.

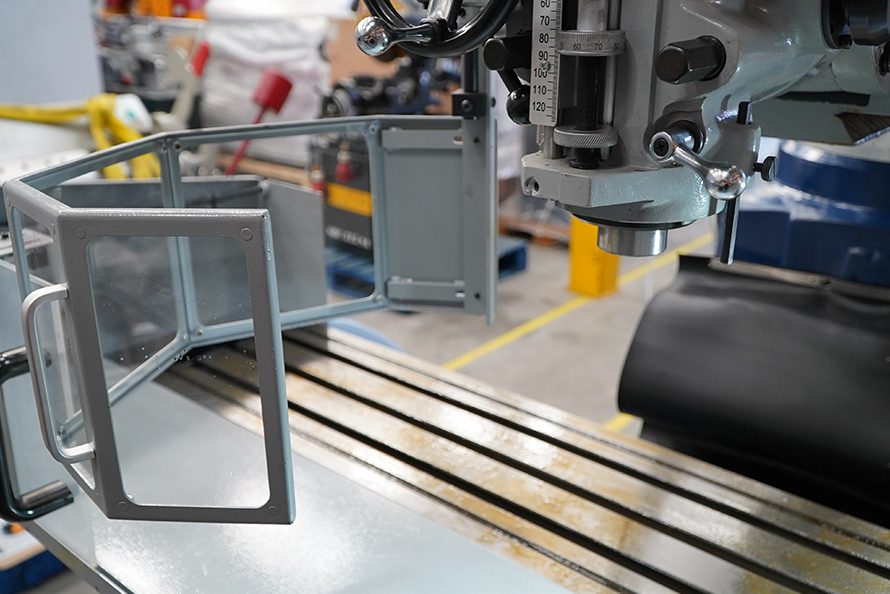

- Large table with T slots.

- Tapping facility.

- Motor brake lever.

- Coolant system.

- 220R/220RX – R8 tooling with power X axis.

- 375S/560S – ISO40 tooling with power X, Y and Z axis.

- Halogen lamp.

- Safety guard with interlock.

- Swarf Tray.

Options

- Powered X, Y and Z Axis (220RX)

- Inverter driven variable speed

- Slotting Head Attachment